Overview

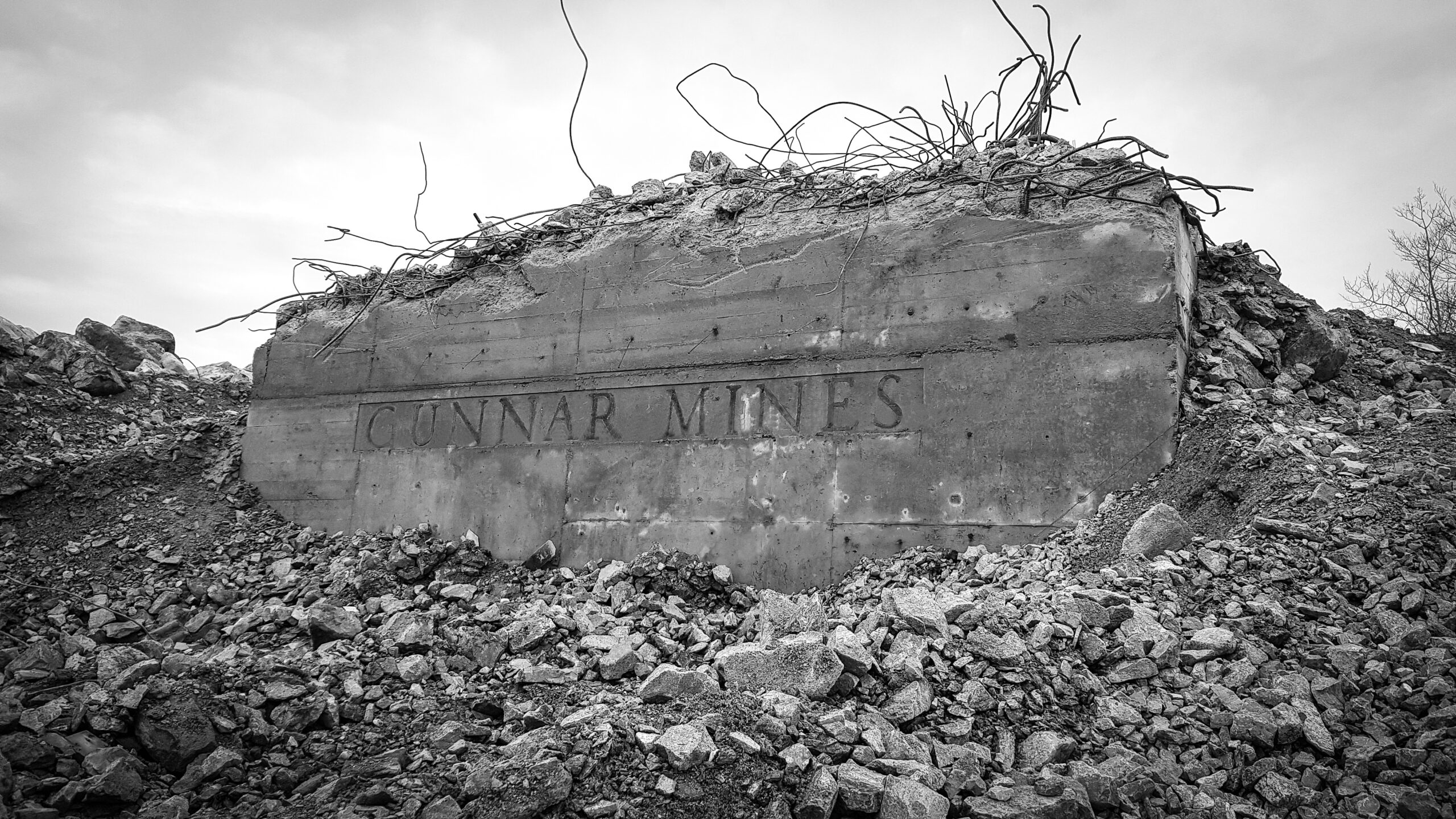

In June 2019, QM Environmental, through its limited partnership with Point Athabasca Contracting LP (“QM Points LP” or “QMP”), was awarded the Gunnar Mine Other Site Aspects Remediation Project by the Saskatchewan Research Council (“SRC”). The Gunnar Mine Other Site Aspects Remediation Project is part of the Government of Saskatchewan and Government of Canada efforts to assess and reclaim abandoned northern Saskatchewan uranium facilities (Project CLEANS or Clean-up of Abandoned Northern Sites). The SRC is tasked with managing the remediation of the former Gunnar Mine and Mill Site on behalf of the Government of Saskatchewan. The Gunnar Mine and Mill Site poses potential risks to the surrounding communities and environment due to limited previous efforts into decommissioning of abandoned mills and mines in Saskatchewan. The project involves remediation of the Gunnar Mine site to reduce the overall risk to the immediate environment and to transform the Site to its natural use to allow for re-establishment of vegetation and traditional use of the land.

The Gunnar Mine and Mill Site is a former uranium mine located on the north shore of Lake Athabasca in northern Saskatchewan, roughly 68 km south of the Northwest Territories and Saskatchewan border. Mobilization to a site as remote as the Gunnar Mine Site is extremely complex. Working at the Gunnar Mine Site requires extensive planning, precautions and proper sequencing for successful completion due to inclement weather, difficult access and shortage of local supplies. Transportation and logistics present major risks to the execution of a remote northern project. The project site is only accessible via small aircraft or barge for five months of the year, with winter road access limited to 3 weeks in springtime. Therefore, an approach that reduces risk associated with the available window to utilize the Lake Athabasca winter/ice road is necessary.

The project aims to reduce the risks the Site poses, in its current state, to the health and safety of the public and the environment. Remedial planning has focused on a concise list of site aspects for major contaminant source and/or risk areas at the Site; including the uranium tailings deposits, as well as Other Site Aspects. Specifically, the remediation project objectives and endpoints are:

• Containment and stabilization of the unconfined tailings and waste rock piles to minimize human health risks posed by gamma radiation;

• Minimization of contaminant releases from the tailings and waste rock to Lake Athabasca;

• Permanent disposal of all waste materials in a manner that is environmentally sound and meets regulatory requirements;

• Remediation and contouring of the landscape in a manner that is compatible with the natural surroundings and future use of the Site; and

• Taking measures to ensure conventional health and safety.

Summary of Work Completed to Date

The Canadian Nuclear Safety Commission and Saskatchewan Ministry of Environment regulated project involves the following tasks that are currently 48% complete:

• Development of approximately 400,000 m2 of local borrow areas. The borrow areas required pre-construction surveys, rare plant species surveys and heritage surveys before borrow development could be started.

• Construction of an engineered cover system over waste rock piles using 230,000 m3 of backfill material extracted from local borrow areas;

• Construction of two Landfill (s): “Landfill A -Non-Hazardous” and “Landfill B – Hazardous”;

• The construction of Landfill A includes several indirect work scopes that are completed at various stages to accommodate the waste streams destined for final disposal at Landfill A. The Landfill A design has been subject to design change, which included the placement of asbestos-containing material (ACM) within the Landfill A footprint as a final disposal location. While the primary drawings indicated a trench was to be excavated to facilitate ACM disposal, a test pitting investigation revealed the presence of bedrock and eliminated this approach as a possibility. Alternatively, it was proposed to amend the disposal trench design location and employ the use of waste rock from the Gyratory Crusher excavation to construct waste rock separations. These separations would be used to segregate the ACM from the non-hazardous waste within Landfill A. QMP facilitated the construction of the waste rock separations, completing waste rock placement along with the northern extent, and continuing along the eastern edge.

• Landfill B is a non-pervious, small containment cell where all Landfill B-designated waste such as Low-Level Radioactive Waste (LLRW), pH and/or petroleum hydrocarbon-impacted material with levels exceeding the maximum allowable concentrations, and earthen material (soil/waste rock) will be placed in accordance with the Remediation Design Documents. On August 1st, 2019, QMP commenced preliminary activities at the Landfill B area in accordance with the Remediation Design Documents. These initial activities included test pitting, moving LLRW into bags, and handpicking acidic bricks. Several activities were performed in connection with the Landfill B construction and preparation, which include:

• Demolition and waste concrete removal, excavation of soil to bedrock; bedrock Investigation, and geomechanical bedrock investigation and cleaning Legacy waste cleanup within the historical mine administration boundaries; These waste types were generated during the historical operation on the mining operations; Typically discovered legacy waste consisted of various amounts of industrial, general and hazardous materials abandoned throughout the Site including concrete, scrap metal, wood, tires and regulated wastes (oil filters, residual reagent chemicals, etc);

• Transportation, placement, and disposal of approx. 14,000 m3 of asbestos-containing materials generated from the demolition phase of the project; QMP has developed an Asbestos Control Plan (“ACP”) to establish a process to be used to identify, inspect, control, maintain and properly handle asbestos-containing materials at the Gunnar Site. The ACP ensures that risks associated with asbestos-containing materials are addressed in the most expeditious manner possible in order to reduce negative environmental impacts or adverse health effects to workers and visitors. In addition, QMP provided respiratory protection and asbestos training for all workers to prepare for work related to asbestos. As part of the abatement and demolition activities on the Gunnar site, friable asbestos was double-bagged and is being safely stored in the dock warehouse until a final disposal location has been approved. Non-friable asbestos was wrapped in Super Sacks and is being stored in designated areas, with appropriate signage, in compliance with regulatory requirements.

• Consolidation, treatment, and disposal of 3,500 m3 of petroleum hydrocarbon contaminated soils and rock; Bulk volume of the acidic soil and potentially acidic generating material (pH impacted materials) to be excavated and treated are located at the former acid plant area due to storage of elemental sulphur and processing of sulphuric acid in the area. Excavation of the pH impacted material, waste rocks and concrete from the area is a priority task due to its connection with the Landfill B construction. QMP commenced excavating the pH impacted soil on August 23rd, 2019, using heavy construction equipment such as excavators, concrete breakers, skid steer, haul trucks, grader, loader, and screener. In line with the guidelines set in the Corrective Action Plan (CAP) report, the screened acidic soil was treated with lime to neutralize the acidic content; hauled the treated material to the designated temporary stockpile towards the north of the mixing pad. QMP completed the substantial excavation/removal of impacted materials at the Landfill B area.

• Consolidation, screening, amendment treatment and disposal of 23,000 m3 of sulphur contaminated soils and rock;

• Drilling and Blasting approx. 90,000 m3 of rip rap material for placement on all slopes greater the 2:1. Riprap material is placed because it offers improved erosion control characteristics. Excavation of two historical drainage channels (former creeks) impacted with tailings material. The channels will be excavated and restored, reducing contamination loading of water percolating through the waste rock piles;

• Construction of 8 km of haul roads designed to meet Saskatchewan mining regulations. Haul road development has included improvements to existing road infrastructure and construction of engineered haul routes into developed borrow areas. Haul roads traverse through fish-bearing waterways, standing water areas, and environmentally sensitive areas;

• Construction and installation of three stainless steel engineered mine opening caps; The opening include the head frame opening, back raise opening and vent raise opening. The previous demolition scope included the construction of temporary concrete caps, which have been removed and will be replaced with the stainless steel caps. The stainless steels caps offer increased durability and lifespan over typical concrete caps;

• Construction of a cover over the general site area as identified in the Remediation Design Documents. Being a historical uranium mine has left the site with potential gamma-emitting dust and waste rock. While waste rock was used predominantly throughout the site to construct road and lay down areas, it also increases the chance of radiation exposure. The cover system provides a one-meter barrier of soil, which eliminates and gamma radiation exposure; and

• To achieve project objectives, QMP has employed a diverse fleet of leading-edge survey equipment which Includes fixed-wing and copter style drone Unmanned Aerial Vehicles (“UAVs”), and GNSS positional control on both our excavator and dozers. Utilizing UAV survey data collection allows for accurate collection of daily productivity, material stockpile volume survey, daily as-built surfaces, and planning haul road alignments. Once survey data is collected, a digital 3D model is rendered and quality controlled against the Construction Design Documents. QMP is also launching the Trimble RECAP app to develop and produce drone Orthomosaic data into virtual walk-through tours.

A large equipment fleet was utilized during the 2019 and 2020 field seasons including four excavators (sized 28 MT to 51 MT), one loader, one grader, two bulldozers, and five rock trucks (sized 30 MT to 40 MT).

QMP’s commitment is to provide a safe workplace to its employees and protection of the environment while minimizing loss of property damage. QMP developed and implemented site health and safety policies as part of the Health and Safety Management Plan for the Gunnar Mine project. QMP was able to achieve a zero lost time injury during the 2019 field season which is our topmost priority to ensure the safety of our employees.

In response to COVID-19, QMP has initiated a COVID-19 Contingency Management Plan and a COVID-19 Site Response Plan. The COVID-19 Contingency Management Plan was developed to aid in the understanding of project-related impacts, risks, and mitigations. The plans also aim to evaluate the key interests of the project including protecting resources, minimizing customer inconvenience, identifying key staff, and assigning specific responsibilities. To ensure a safe working environment, the COVID-19 Site Response Plan was developed to outline preventive and control measures as well as guidelines that have been implemented to reduce the risk of spread of COVID-19 infection during QMP’s daily remediation activities at the Gunnar Site. The plan also lists precautionary measures taken by all QMP employees and subcontractors prior to their arrival at the Gunnar Site.

In addition, QMP developed a site-specific traffic control plan (“TCP”) to establish the site-specific procedures to provide a safe and efficient manner for transportation of equipment, vehicles, materials and personnel on and off the site. This TCP is intended to be a practical document that provides guidance to project personnel during the work activities in order to protect personnel, the environment, and minimize potential adverse effects.

QMP has worked closely with SRC to obtain the required Fisheries and Oceans Canada (“F&OC”) request for project review and approvals for work within water bodes at the Gunnar Mine site. QMP has performed work adjacent to water bodies and within the high watermark of Lake Athabasca. QMP has also performed work on two historical drainage channels impacted with tailings material. Historical tailings material found within the water bodies and drainage channels has been removed using excavators equipped with GNSS positional control. The strategies for erosion and sediment control for work adjacent to water bodies involved the installation of silt fencing, floating silt curtains, and employing excavation practices that manage erosion.

A Project Execution Plan has been developed to provide a detailed approach to progressive borrow development and reclamation. Clearing and grubbing will be completed and vegetation and organics will be stockpiled for future use in reclamation. Also, under the Gunnar Revegetation QMP will be completing all the revegetation at the Gunnar Mine Site using a small disking harrow to broadcast native seeds and fertilizer.

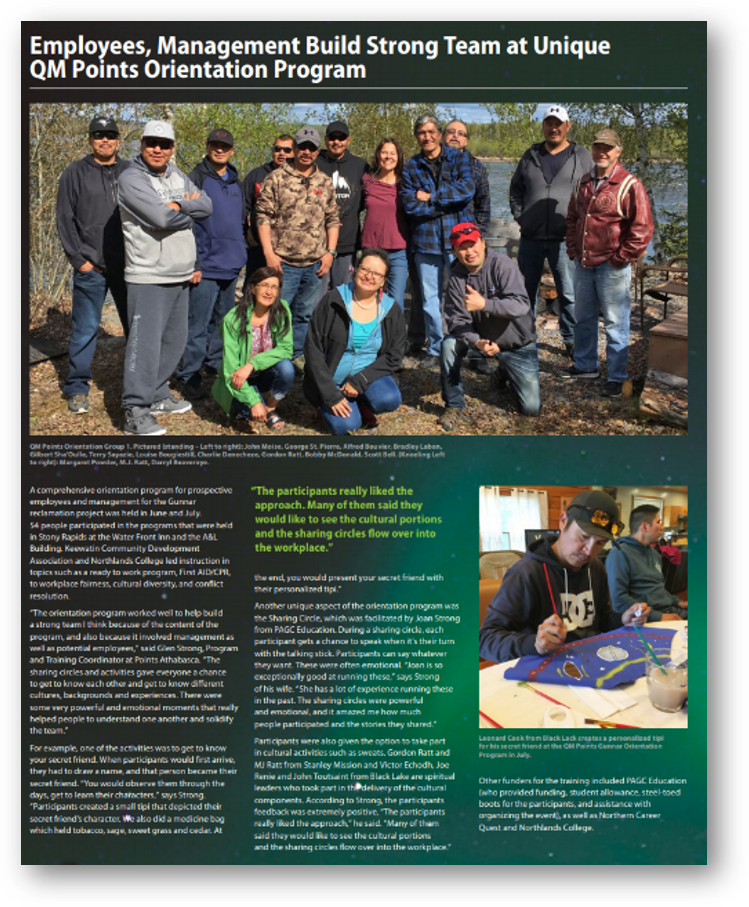

Meaningful community engagement is key to the successful completion of the Gunnar Mine Site Remediation. Developing cooperative and inclusive relationships with the three First Nations within the Athabasca Basin is of the utmost importance in establishing a social license to participate in this remote remediation project. Implementing practical and robust methods to ensure opportunities for local First Nations employees from entry-level labour to supervisory and management positions was integral to operational optimization.

As per the agreement with SRC regarding the Athabasca Basin Region Aboriginal persons target, it remains expected that QMP will achieve its target of 60% as a minimum average calculated at the project’s end. The total number of onsite hours worked by Athabasca Basin Region Aboriginal persons has been tracked via daily demographic calculations. Based on the average of the daily recordings, it was found that 75% of total onsite hours were contributed by Athabasca Basin Region Aboriginal Persons. Also, the Athabasca Basin Region owned Heavy Equipment showed an average of 85%. Both the labour and heavy equipment numbers exceeded the Athabasca Basin Region Aboriginal targets as per the agreement with SRC.

The overall goal with respect to social and economic sustainability is to properly engage, include and support the Athabasca Basin Region throughout the length of the project in a manner that serves the region’s communities and people for years after the project ends.

For more information regarding QM’s Remediation services, visit our Remediation webpage.

Project Info

Client:

Saskatchewan Research Council

Project Timeline:

2019 – 2024

Location:

Uranium City, Saskatchewan

Indigenous Participation:

75%